You are probably already very familiar with these challenges:

- Previously, you had to coordinate several service providers for the planning, development, manufacture, storage and delivery of your plastic parts. This requires a tremendous amount of resources, and entails the risk of your processes not running as reliably as you would like.

- You have developed an innovative product idea, but you are struggling with the implementation thereof. You are in desperately need of a way of turning your idea into a tangible, high-quality product within the scope of your resources.

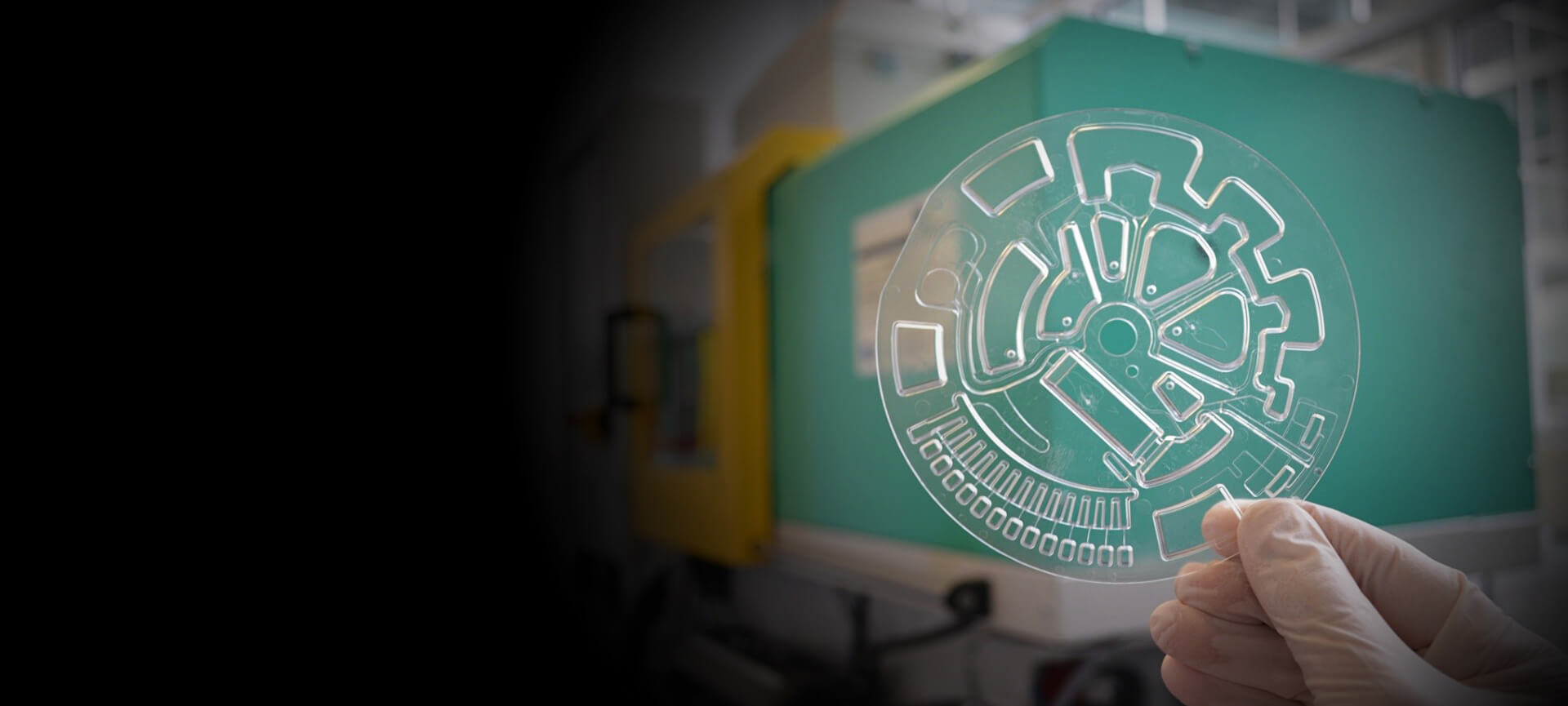

- You need plastic components which provide maximum precision within hundredths of a millimetre as well as robustness, and can also be mass-produced.

Your benefits from our expertise

-

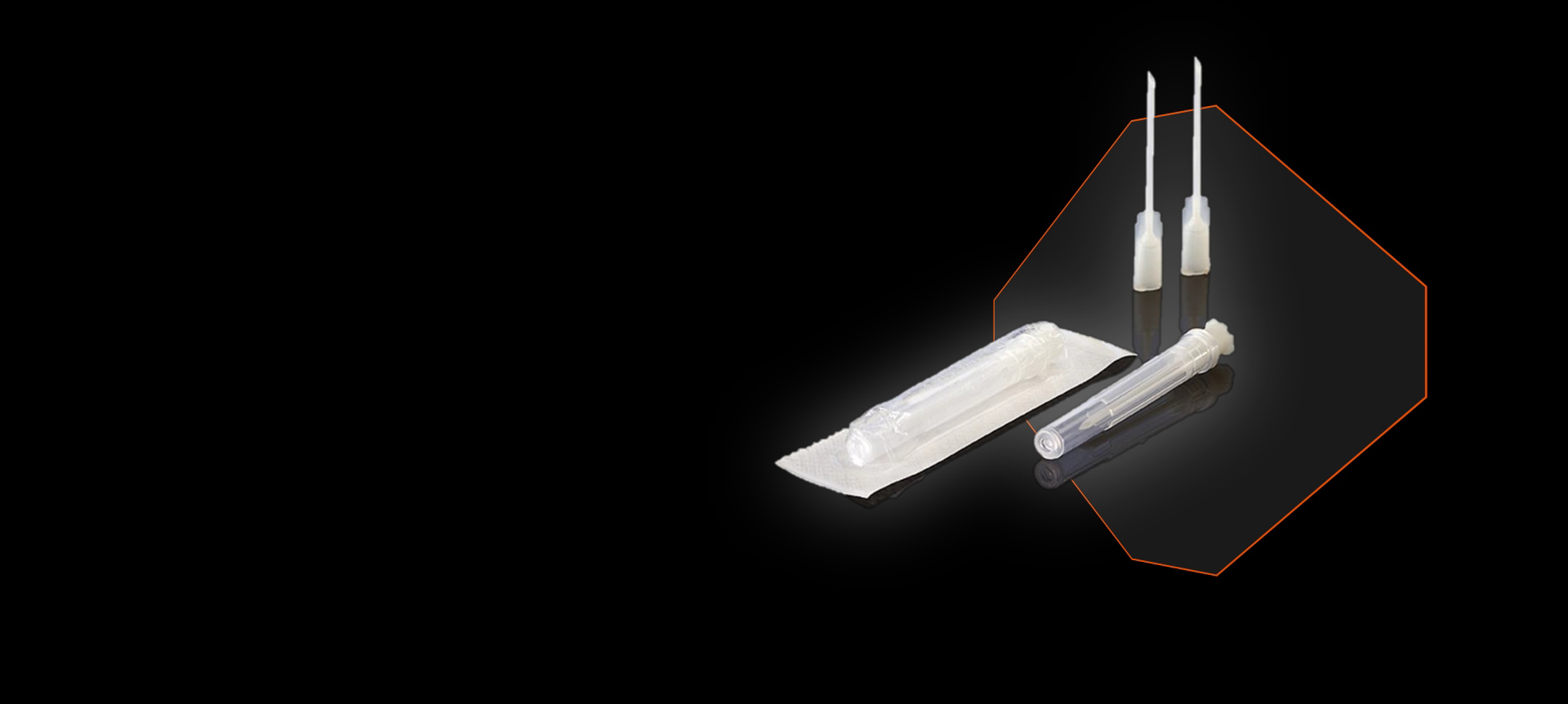

Reliable processes from a single source: At Otto Klumpp you get everything you need for high-quality products and efficient processes, from the planning to the delivery of your plastic parts.

-

Your innovative idea is turned into a tangible product: We develop your product idea with you and for you, so that your vision becomes a tangible product without blowing your resources during development and production.

-

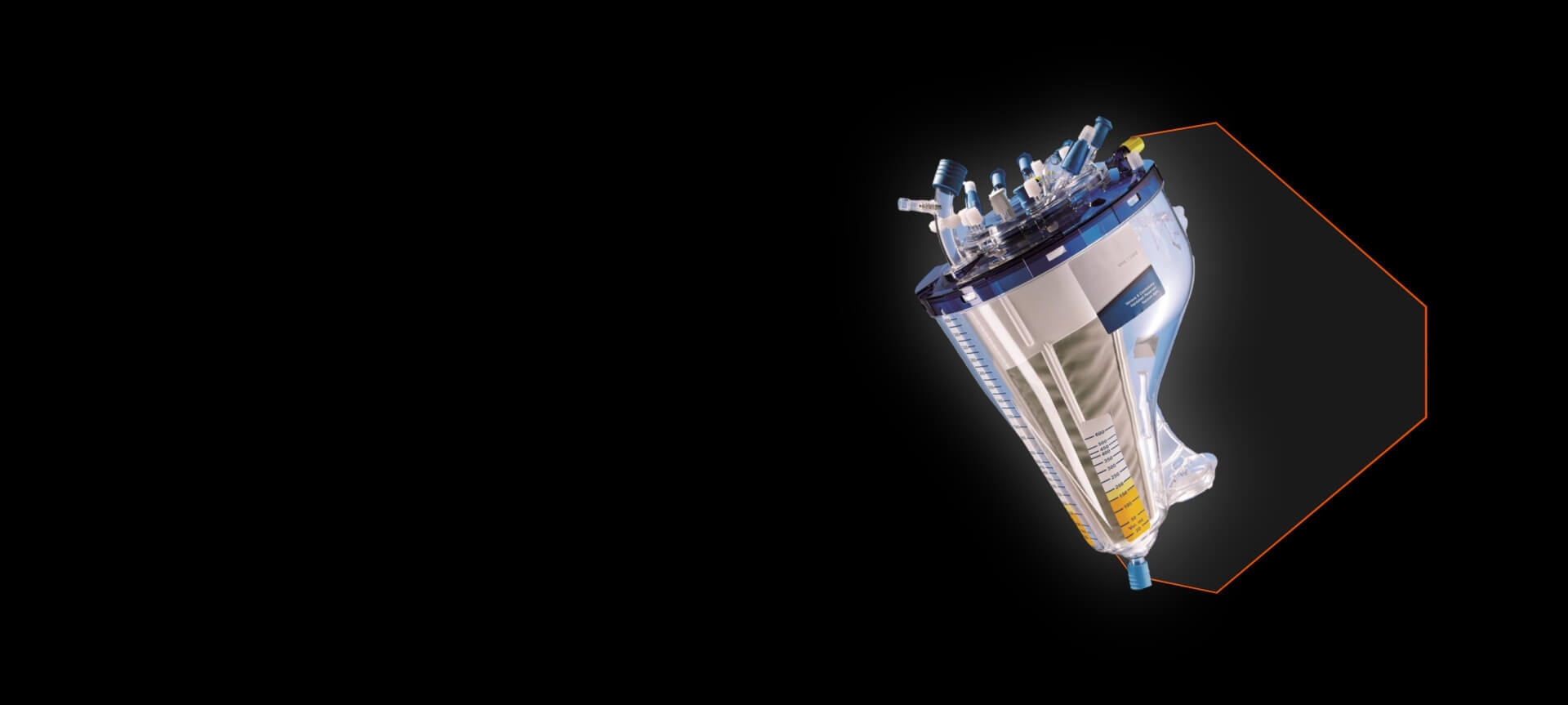

Robust plastic components for complex technology: We develop, manufacture, finish and assemble your robust and precise plastic components using well-tried processes and modern tools.

Serial buyer

Decision-maker

You will get to know Otto Klumpp better here

THE OTTO KLUMPP GUARANTEE:

Almost 100 % of the visitors to our production facility on site decided to cooperate with Otto Klumpp. Why? Find out for yourself.

The company

Otto Klumpp is a family-run company which was established by master mechanic Otto Klumpp in 1961. The company’s main activities are the development, manufacture and sale of injection moulded items made from plastic and injection moulding tools.